In today's fast-paced manufacturing and production

environments, selecting the right adhesive isn’t just a detail—it’s a critical

decision that can affect product quality, durability, safety, and even brand

reputation. Whether you're in automotive, packaging, construction, electronics, or

healthcare, the right bonding solution ensures seamless performance and long-term

reliability.

Why the Right Adhesive Matters

Adhesives are no longer one-size-fits-all. Modern

engineering and material science have evolved to produce specialized bonding agents

tailored for various substrates, environmental conditions, and application methods.

The wrong adhesive can lead to:

- Product failure or breakdown

- Increased production downtime

- Higher warranty costs

- Compliance and safety issues

Choosing the right adhesive means better efficiency, stronger products, and reduced

long-term costs.

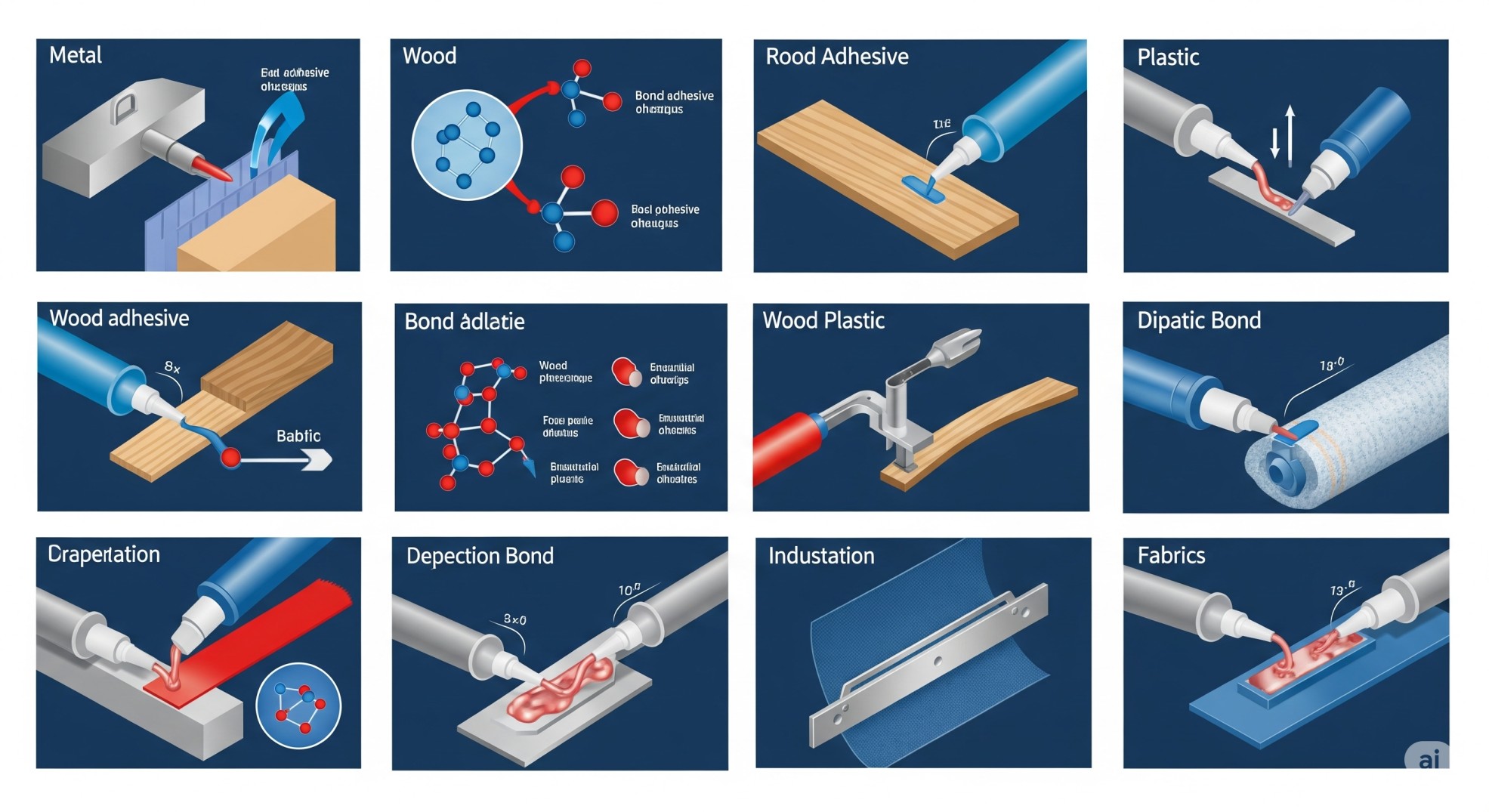

Key Factors to Consider

1. Material Compatibility

Different adhesives work best on specific materials—metal, plastic, wood, glass,

composites, or fabric. For instance:

- Epoxy adhesives are ideal for metals and structural bonding.

- Cyanoacrylates (super glues) work well on plastics and rubbers.

- Polyurethane adhesives offer flexibility and are great for wood and construction

materials.

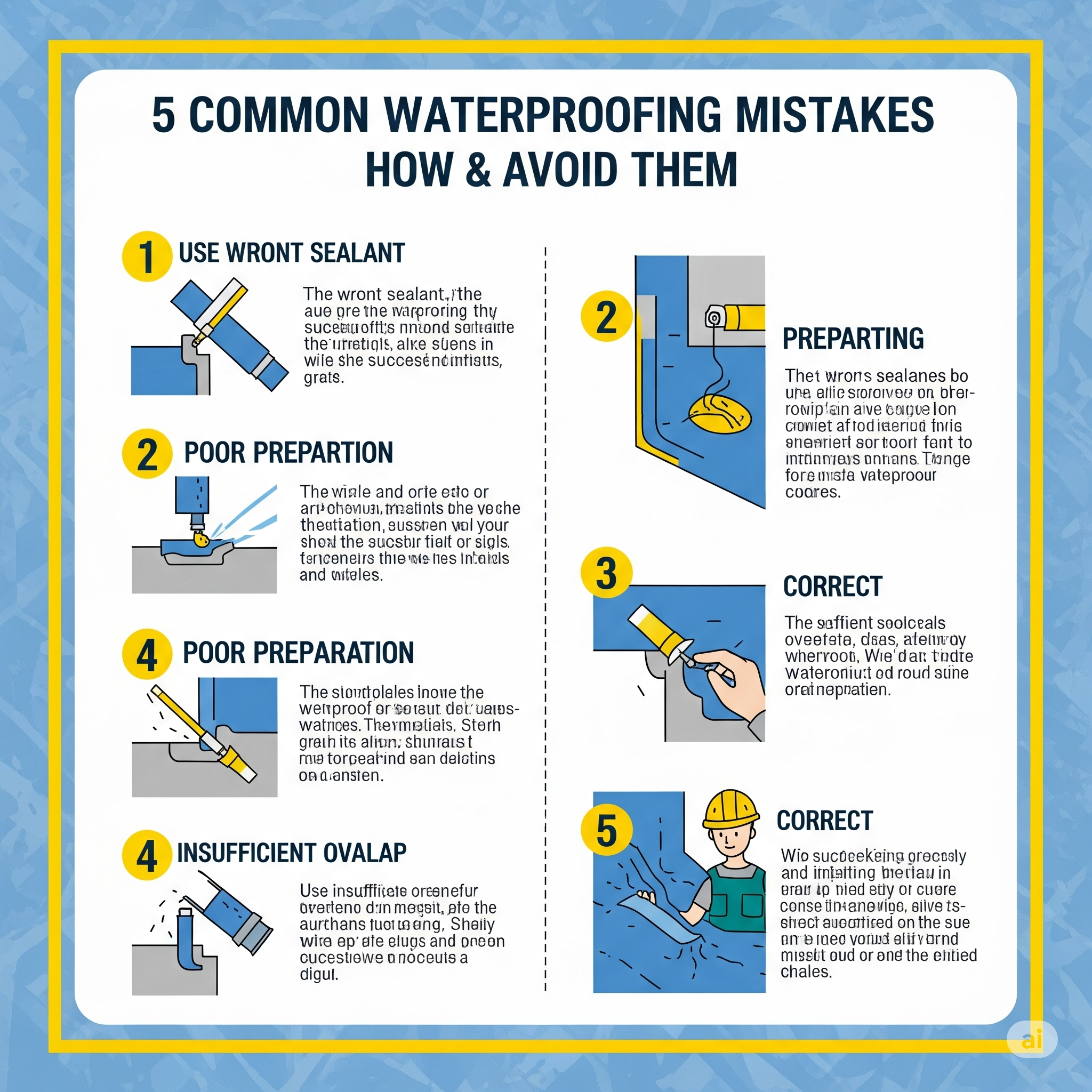

2. Application Environment

Will the bonded product face moisture, heat, UV exposure, or chemicals? High-performance

adhesives like silicone or acrylics are resistant to harsh environmental conditions and

are often used in automotive, aerospace, and outdoor construction.

3. Strength and Flexibility Requirements

Do you need a rigid bond for structural integrity or a flexible one to withstand

movement or vibration? Epoxies provide high shear strength, while silicone and

rubber-based adhesives offer flexibility.

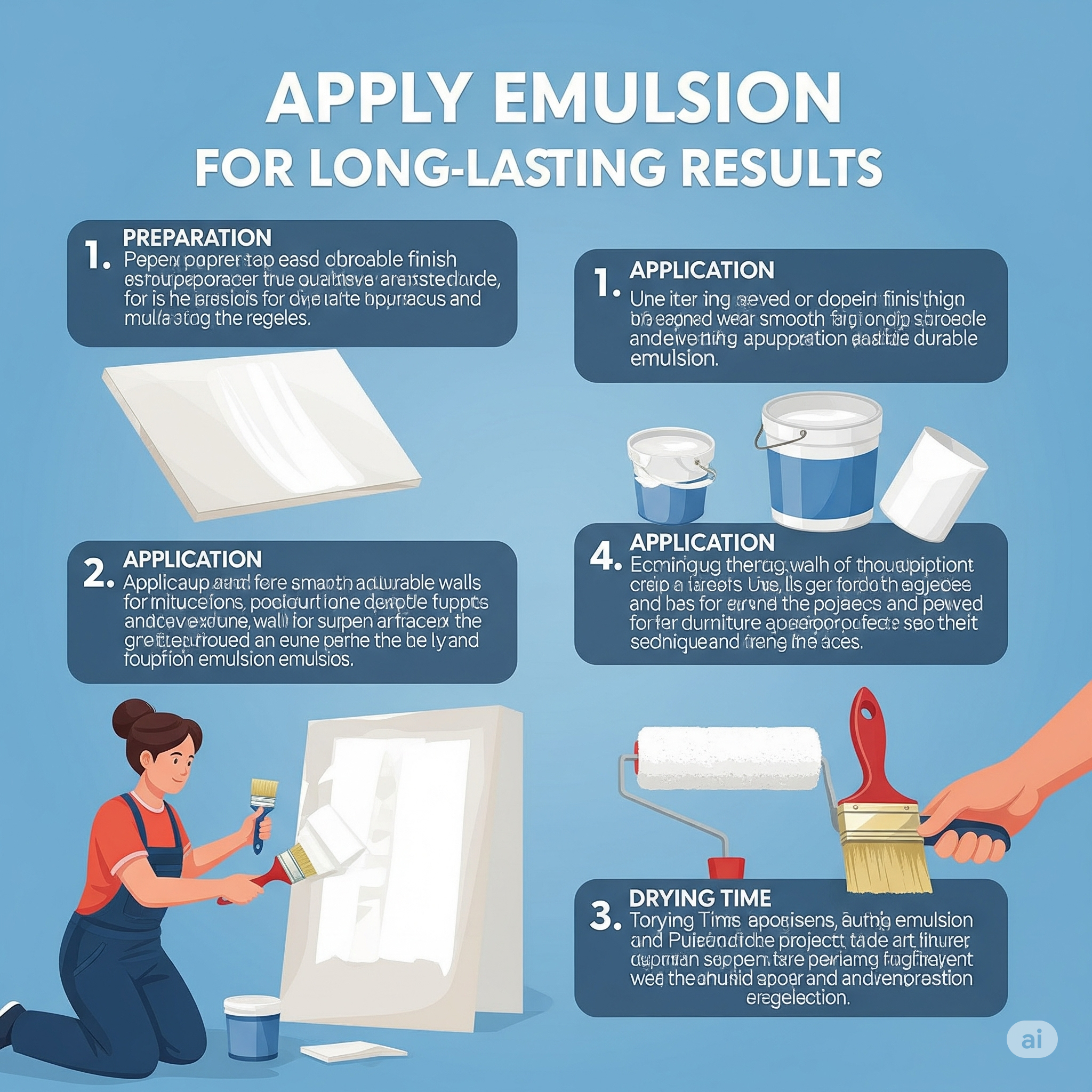

4. Curing Time and Application Method

In high-speed production lines, fast curing may be a necessity. UV-cured adhesives and

hot melts are used for rapid bonding. Also consider whether you'll apply the adhesive

manually or via automated dispensing.

5. Regulatory and Safety Standards

In industries like food packaging, medical devices, or electronics, adhesives must meet

specific certifications (e.g., FDA-approved, RoHS-compliant, or biocompatible).

Industry-Specific Adhesive Recommendations

Automotive

Use structural adhesives (epoxies, urethanes) for chassis and interior assemblies.

Heat resistance and vibration tolerance are key.

Packaging

Hot melt and water-based adhesives work well for carton sealing, labels, and

flexible packaging.

Electronics

Epoxies and silicone adhesives protect circuits from moisture and heat while

ensuring conductivity where needed.

Construction

Polyurethane and hybrid sealants offer excellent adhesion, elasticity, and weather

resistance for flooring, panels, and roofing.

Medical

Biocompatible adhesives like UV-cured acrylates are used for assembling medical

devices with precise bonding needs.

Conclusion

Selecting the right adhesive is a strategic decision

that should align with your product's materials, use case, and performance

expectations. Consulting with an adhesive expert or supplier early in the design

phase can help you avoid costly issues down the line and unlock better product

innovation.

Need help selecting the right adhesive for your business? Reach out to our material

specialists today for personalized guidance.

Leave a Comment